POST-HARVEST

For almost 60 years, Agri-Stor has innovated your Post-Harvest Solutions with University-based Research and years of applied data. We were the reason Post Harvest began. And you’ll be the reason why we continue on.

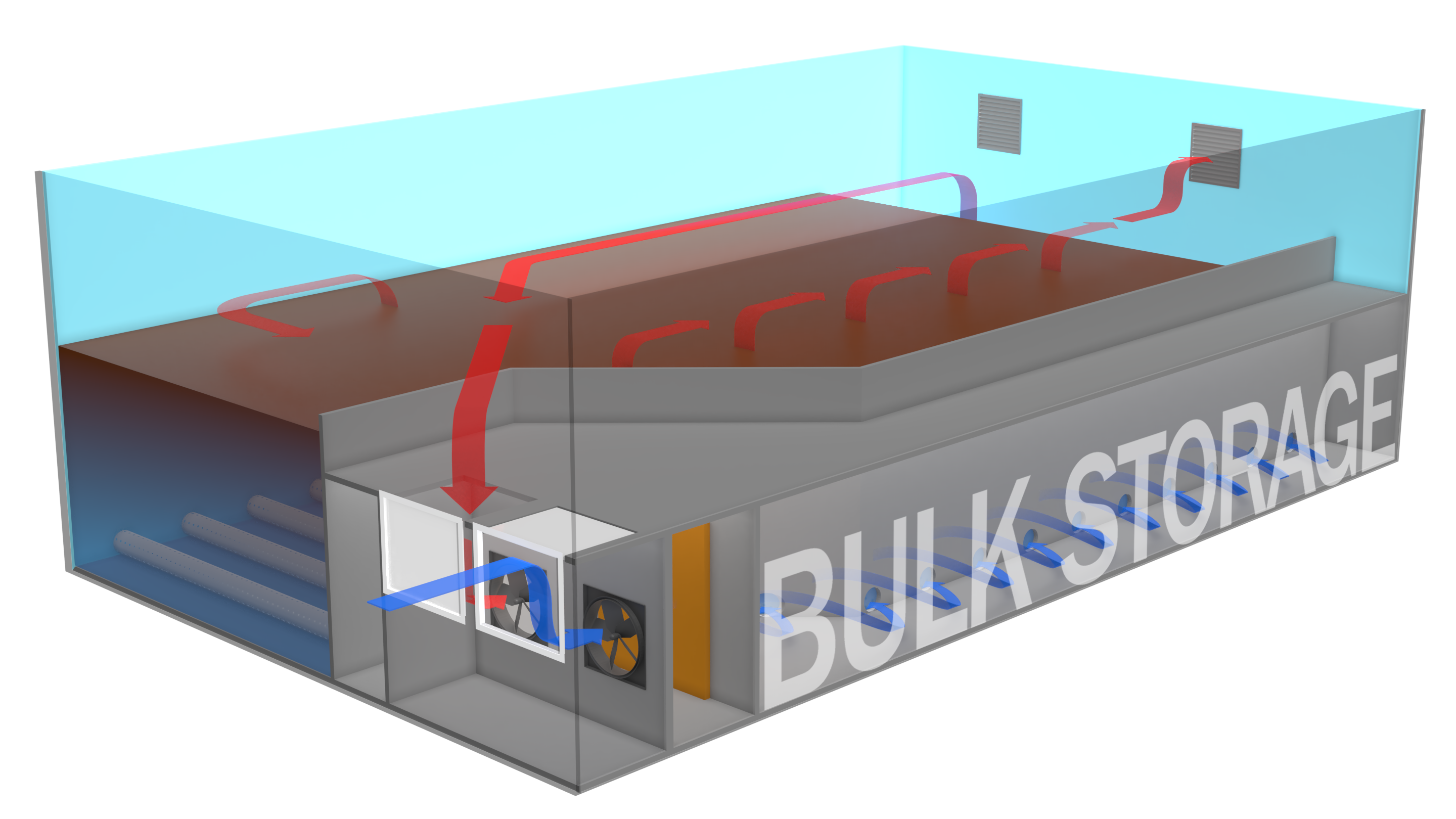

BULK STORAGE

Bulk storage is product held on the ground with air floor slots or duct that include holes that feed the air up and through the pile. Options include internal or external fan house. Air control through the product comes from duct opening hatches that manually open and close.

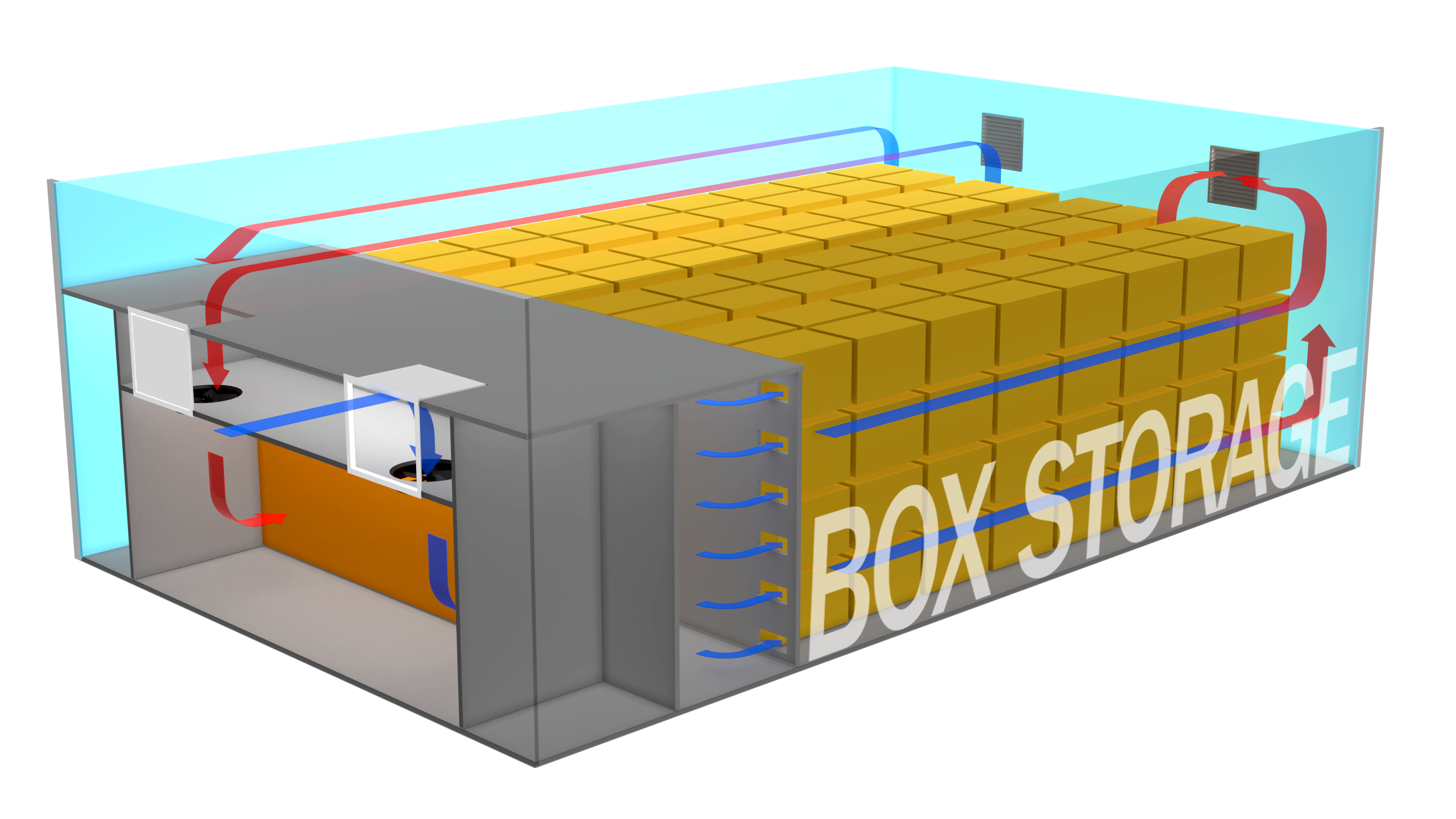

LETTERBOX STORAGE

Letterbox Design feeds air through slots in the wall in and around boxed product. Our first Letterbox Storage was designed in 1965. Options include cross vent and external and internal Fan House. Letterbox design can also include cross ventilation or a consolidated fan house with Gellert Return Air Scoop.

GELLERT’S PROPRIETARY EQUIPMENT AND CONTROLS

Agri-Stor Company has worked with Gellert Company for over 50 years in the Post-Harvest Storage Industry. CLICK HERE for more information on how our companies work together to provide the best storage environment for your hard-earned investment!

FANS

Where Post Harvest Ventilation is concerned, Gellert doesn’t cut corners, there’s too much at stake. All fans are AMCA Certified. This is key to performance and also to qualify for utility incentive programs and meet life and standard criteria. It’s a tough test – but our customers deserve it. CLICK HERE for more information.

HUMIDIFIERS

Gellert’s Centrifugal Humidifiers provide a simple solution to humidification needs as they are completely self-contained. Specifically designed for minimum maintenance, all parts coming in contact with water are made using stainless steel, copper, brass, and aluminum to aid in corrosion resistance. CLICK HERE for more information.

REFRIGERATION

Inconsistent seasonal temperature challenges are easily solved with Refrigeration. Gellert can help with a variety of affordable solutions depending on your budget. From Fixed Condensing Units, Portable, Unit Coolers and more Gellert can adapt to your refrigeration needs. CLICK HERE for more information.

CONTROLS

The Gellert Company Agri-Star™ Control Panel features a large, full-color touch screen display with complete on-screen graphing. Comes internet-ready with no proprietary software to operate, a user friendly, clear operating interface, on-board help menus, and software flexibility to control both Potato and Onion systems. CLICK HERE for more information.

FRESH AIR DOORS

Gellert’s ClimaSeal Fresh Air doors are custom-sized specifically for your Gellert Certified ventilation system. CLICK HERE for more information.

EXHAUST DAMPERS OR LOUVERS

Gellert’s Ruskin® Backdraft Exhaust Dampers are gravity operated and open with air flow and pressure. Every damper is built with performance in mind and tested per AMCA standards in Ruskin’s Laboratory. Backdraft design prevents air from entering the building through the Exhaust Dampers. Damper blades are constructed from .050” thick extruded aluminum with extruded vinyl blade edge seals and are mounted in an aluminum frame with synthetic bearings. Gellert’s Ruskin® Backdraft Exhaust Dampers provide high performance with minimal maintenance to guarantee a long operational life.

GDC CONTROLLER

Gellert’s GDC Door Controller is simple to operate, reliable, and provides precise control of ClimaSeal Doors or Fresh Air Louvers. Service features include status indicating LEDs for all signal power and fusing and full manual override of all control functions to insure simple trouble shooting.

LINEAR ACTUATOR

The Gellert Linear Actuator features a potentiometer for precise positioning and integral adjustable limit switches to automatically shut off actuator within desired operating ranges. Housing and motor are fully sealed to protect all internal components from harsh environments. When integrated with the Gellert Control Panel, the actuator offers precise temperature control and is available in a variety of stroke lengths.

Visit Us

Twin Falls, Idaho

Blackfoot, Idaho

Warden, Washington

Monte Vista, Colorado

Merrill, Oregon

Coaldale, Alberta CANADA

Contact us

TWIN FALLS, ID: 208.733.7000

BLACKFOOT, ID: 208.785.7000

WASHINGTON: 509.349.7000

COLORADO: 719.850.7783

OREGON: 541.798.5655

ALBERTA, CANADA: 403.715.6960